In modern commercial kitchens, fried foods still occupy an important position. From fast food chains to high-end restaurants, whether it is golden and crispy French fries, crispy fried chicken, or various snacks with unique flavors, fryers are almost indispensable kitchen equipment. Among the many types of fryers, open fryers have gradually become the first choice of chefs and equipment purchasers in the industry due to their excellent operating convenience, efficient heat conduction ability, and flexibility to adapt to various frying needs.

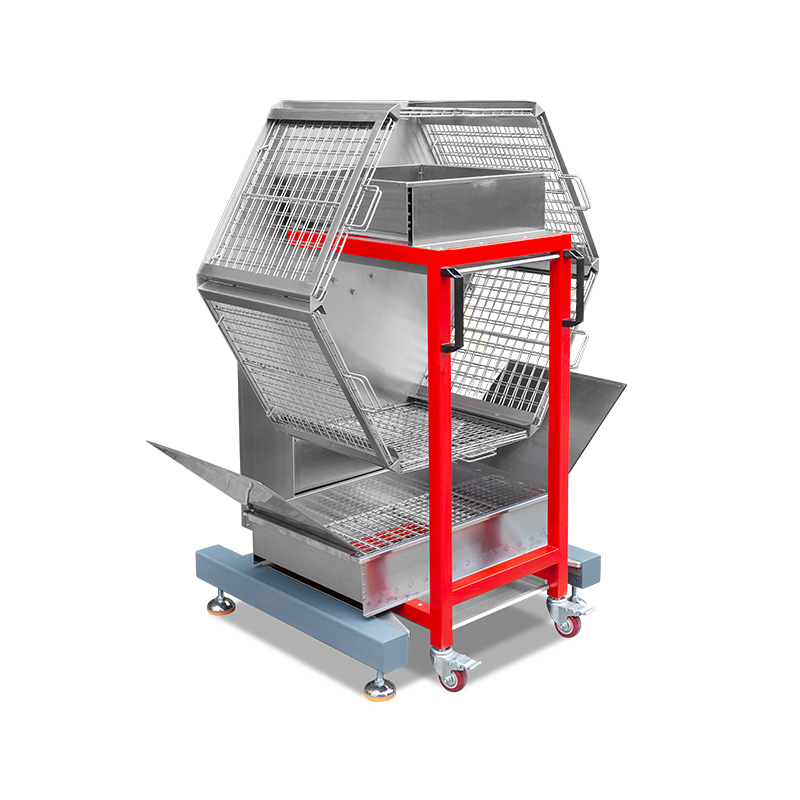

Open fryers usually refer to traditional deep fryer equipment without a closed structure. The heating elements of this type of fryer can be gas or electric heating, and the heat energy is directly transferred to the cooking oil through the oil cylinder, thereby achieving fast and uniform heating. Compared with closed systems such as pressure fryers, the biggest advantage of open fryers is the intuitive and convenient operation brought by their open structure. Chefs can easily observe the state of food during frying and make adjustments quickly, which greatly improves cooking control and efficiency.

From a design perspective, modern open fryers have achieved many aspects of optimization based on traditional structures. The first is the improvement of thermal efficiency. High-quality open fryers usually use precise temperature control technology and efficient heat exchange systems, which can quickly respond to temperature fluctuations caused by large-scale food delivery while maintaining a constant oil temperature. This is crucial for fast-paced commercial kitchens. Upgrade of oil management system. The current mainstream brand equipment is often equipped with an intelligent filtration and circulation system, which can complete the filtration and cleaning of oil in a short time, which not only extends the service life of edible oil, but also significantly improves the hygiene standards and taste performance of food.

In the context of increasing attention to food safety and energy consumption issues, the energy-saving and environmental protection properties of open fryers are also favored. Many new fryers have introduced energy-saving modules such as automatic on/off, standby insulation, and low oil operation, which effectively reduce energy consumption and operating costs. In addition to the compatibility of built-in fume control components or external fume purification equipment, open fryers play an increasingly important role in the construction of modern green kitchens.

In addition to the improvement of technical performance, open fryers also show a humanized development trend in terms of operating experience. Whether it is the introduction of programmable control panels or the setting of high-brightness LED displays and fault diagnosis systems, they all reflect the importance of user-friendliness. These intelligent and user-friendly designs not only lower the threshold for use, but also greatly reduce the workload of chefs, allowing them to focus more on the quality of the food itself.

The application of open fryers is not limited to traditional fried food restaurants. It has become one of the important equipment in various diversified catering models. For example, in fusion cuisine, open fryers are often used to make Southeast Asian-style fried fish, Thai spring rolls, etc.; in food street stalls, it becomes the main tool for making exploding cheese balls and creative fried vegetables. The diversity and adaptability of this equipment is the key to its long-term competitiveness in the catering equipment market.

English

English

عربى

عربى